MXGWR

Achieve unparalleled precision in level and interface measurement for liquids with our cutting-edge technology. Say goodbye to traditional mechanical issues, as our solutions offer enhanced process availability and reliability. Rest assured, safety risks are minimized with our meticulously designed architecture.

Unlock Cost-Efficiencies with MXGWR:

- Immune to density changes, ensuring consistent performance.

- Maintenance-free design eliminates the risk of clogging and reduces downtime.

- Swift setup without the necessity of wet calibration.

- Gastight feed ensures optimal safety measures.

- Coated cables provide resistance against corrosion and buildup.

- No requirement for freeze protection or heat tracing, reducing overall operational costs.

Choose MXGWR for your level and interface applications and experience unparalleled reliability and efficiency.

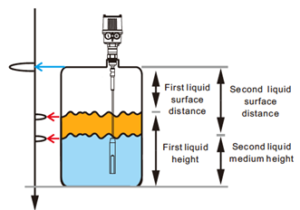

The guided wave radar level transmitter is a solid and liquid level measuring instrument commonly used in the oil and gas industry. It transmits electromagnetic pulses along the coated steel wire cable or tube/rod and propagates at the speed of light; when these encounter the surface of medium to be measured, the pulses will be partly reflected to form an echo wave and returned to the pulse transmission device along the same path, and the height of liquid level and interface level can be calculated. This method is referred to as Time Domain Reflectometry (TDR).

The guided wave radar level transmitter uses advanced echo wave processing technology with a wide range of product applications that is capable of measuring the low dielectric constant of solids level, liquid level and interface levels. The unit has a coated stainless steel wire cable type for the customer’s application, suitable for high temperature and high pressure medium liquid level measurement.

Application specifications:

- Rod, rope or coax probe

- Process connection: Starting at 3/4″ NPT thread, ANSI flange

- Temperature: –40 to +230 °C (–40 to +608 °F)

- Pressure: –1 to +60 bar (–14.5 to +870 psi)

- Maximum measuring range: Rod 10 m (33 ft); rope 45 m (148 ft); coax 6 m (20 ft)

- Accuracy: ±2 mm (±0.08 in)

- International explosion protection certificates

- Linearity protocol (3-point, 5-point)

MXPG

MXPG is ideal for aggressive pressure measurement applications:

- Built in RTD for Temperature compensation

- Modbus RS485 Digital Output

- Easy set-up with Zero Calibration through Display

- Explosion Proof Area Classification

Our Digital Piezoresistive measuring cell incorporates built-in RTD for precise temperature compensation, mitigating errors caused by temperature fluctuations. The RTD accurately reads process temperature, accessible through digital communication output from the transmitter. Choose from metal welded isolating diaphragms crafted in SS316L and Hastelloy materials, ideal for aggressive corrosive environments, including high H2S service. With multiple pressure ranges and high turndown ratio (20:1), minimize inventory levels and optimize versatility across various applications. Designed for gauge pressure, level, and flow measurement, our solutions offer unparalleled reliability and performance.

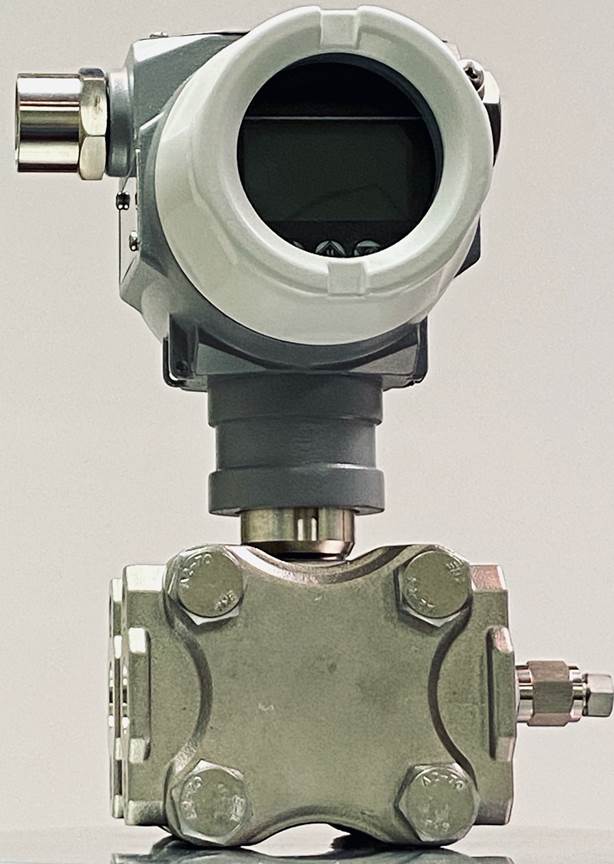

MXDP – Level/Density

MXDP is ideal for aggressive pressure measurement applications:

- Built in RTD for Temperature compensation

- Modbus RS485 Digital Output

- 4-20 mA Output

- Multiple InH20 ranges for a wide variety of applications

- Easy set-up with Zero Calibration through Display

- Explosion Proof Area Classification

MXDP monosilicon pressure transmitter is a high performance pressure transmitter with international leading technology meticulously designed by MPI instrument, using the world’s most advanced monosilicon pressure sensor technology and patent encapsulation technology.

Monosilicon pressure sensor located on the top of the metal body and stays away from the medium interface to realize mechanical and thermal isolation. Glass sintering sensor wire realizes high strength electrical insulation of metal base and improves the capability of flexibility of electronic circuit and transient voltage resistance protection. All these original encapsulation technologies enable MXDP to easily cope with extreme chemical occasion and mechanical load, and strong resistance to EMI, sufficient to respond to the most rigorous industrial environment applications.

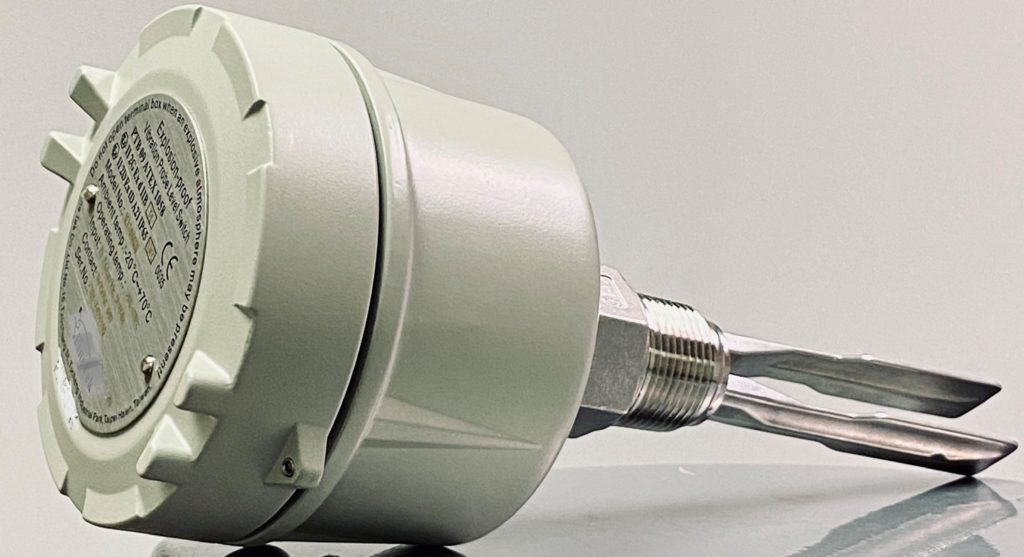

MXLS

MXLS is ideal for aggressive point level/overfill protection measurement applications:

- 20-250VAC/VDC universal power supply

- Solidstate or relay output

- Compact or standard units

- No calibration required

- Mini, standard and extended probe versions

- Capable of detecting low densities such as LPG/LNG mediums.

- Explosion Proof Area Classification

Operating on the principle of detecting vibration frequency changes, our MXLS series tuning fork liquid level switches utilize piezoelectric crystals to create vibrations. These vibrations, transmitted through the forks, are monitored by electronics to detect fluid presence or absence. This innovative technology ensures precise activation of the tuning fork liquid level switch output, delivering unmatched performance in fluid level detection.

MXLS Manual

Krohne Optimass 1400 Straight Tube Coriolis Meter

Optimass 1400 is ideal for aggressive mass flow measurement applications:

- Twin straight tube design

- Entrained Gas Management (EGMTM): No loss of measurement with gas entrainment in liquid applications

- Device commissioning, verification, diagnostics and monitoring via a secure wireless Bluetooth® connection (<20 m / 65.6 ft)

- Fast and completely digital signal processing

- Best-in-class price/performance ratio

- High accuracy mass, density and volume flow measurement (±0.15% of MV)

- Extensive sensor and process diagnostics (incl. NE 107)

- Integrated temperature measurement

- Optimised flow splitter for low pressure loss

- Optional PED approved secondary pressure containment up to 100 barg / 1450 psig

- Optional insulation, heating jacket or purge ports

- Immunity to crosstalk: resistant to installation and process effects

- On-site verification of flowmeter with OPTICHECK service tool

The OPTIMASS 1400 is equipped with an optimized flow splitter to minimize pressure loss and facilitates easy draining and cleaning. It supports various process connections including standard hygienic connections suitable for food and beverage applications. Installation flexibility is guaranteed, as the meter is immune to crosstalk/line vibrations, allowing for series or parallel installations. Additionally, it is approved for use in hazardous areas.

Enhanced diagnostics (NE 107) and multiple digital communication options including Modbus RS485 are available with the OPTIMASS 1400. Manage device settings effortlessly on-site through the secure Bluetooth® connection using the OPTICHECK Flow Mobile app, facilitating wireless commissioning tasks such as zero calibration and diagnostics configuration.

Krohne Optimass 6400 Bent Tube Coriolis Meter

Optimass 6400 is ideal for aggressive mass flow measurement applications:

- Twin bent tube design

- Entrained Gas Management (EGMTM): No loss of measurement with gas entrainment in liquid applications

- Device commissioning, verification, diagnostics and monitoring via a secure wireless Bluetooth®connection (<20 m / 65.6 ft)

- Fast and completely digital signal processing

- Integrated temperature measurement

- Optimised flow splitter for minimum pressure loss

- High accuracy mass, density and volume flow measurement (optional ±0.05% of MV)

- Highest OIML accuracy class of 0.3 for custody transfer (CT)

- SIL2/3 capable up to DN200 / 8″

- Extensive sensor and process diagnostics (incl. NE 107)

- Available in three different sensor materials (incl. Duplex and alloy 22)

- Many options (heat tracing, purge port etc.)

- Self draining when mounted vertically

- Immunity to crosstalk: resistant to installation and process effects

- On-site verification of flowmeter with OPTICHECK service tool possible

Featuring Entrained Gas Management (EGM™) technology for liquid applications, the OPTIMASS 6400 guarantees reliable readings even in scenarios of up to 100% gas entrainment. This Coriolis device ensures continuous and uninterrupted measurement of mass and volume flow, density, and temperature, even in challenging process conditions involving 2-phase flow. The meter holds various hazardous area approvals and is suitable for Safety Instrumented Systems (SIL2/3). It boasts extensive diagnostic functions (NE 107) and multiple digital communication options.

Manage device settings effortlessly on-site via the secure Bluetooth® connection using the OPTICHECK Flow Mobile app. Enjoy the convenience of wireless commissioning tasks such as zero calibration or diagnostics configuration.

MPI MXMAG

The MXMAG-type electromagnetic flowmeter is meticulously engineered to measure a wide range of liquids, including acid, alkali, oil and gas produced water, salt solutions, paper pulp, slurry, and other conductive mediums or liquid-solid two-phase mixtures.

Key Features of the MXMAG Flowmeter:

- Designed to withstand high medium temperatures, making it ideal for oil & gas applications with corrosive liquids.

- Compact and easily accessible transmitter for convenient installation and maintenance.

- Versatile applications supported by a wide variety of wetted materials.

- Energy-efficient flow measurement with no pressure loss thanks to cross-section constriction.

- Maintenance-free operation with no moving parts.

- Comprehensive access to process and diagnostic information through Modbus and other communication buses.

- Secondary/Tertiary Pulse and 4-20 mA Output for enhanced functionality.

- Simple setup and full functional Local Operator Interface (LOI) for seamless operation and control.

The flowmeter for highest medium temperatures with a compact, easily accessible transmitter. Dedicated for oil & gas applications with corrosive liquids and high medium temperatures. Versatile applications – wide variety of wetted materials. Energy-saving flow measurement – no pressure loss due to cross-section constriction. Maintenance-free – no moving parts. Full access to process and diagnostic information – Modbus and other buses. Secondary/Tertiery Pulse and 4-20 mA Output. Easy setup and full functional LOI.

Krohne Optisonic 3400 Ultrasonic Liquids Meter

The OPTISONIC 3400 is a state-of-the-art 3-path ultrasonic inline flowmeter meticulously engineered to meet a diverse range of standard or demanding process applications. It excels in handling homogeneous, non-viscous aqueous liquids, as well as viscous fluids exceeding 1000 cSt. Additionally, it’s perfect for applications involving cryogenic products (as low as -200°C / -328°F), extended temperature ranges (up to +250°C / +482°F), and low or extreme pressure ratings.

Key Features of the OPTISONIC 3400:

- Offers a wide range of diameters, from DN25 / 1″ for dosing purposes to DN3000 / 120″ for water transportation pipelines.

- Utilizes the transit time method, with 3 parallel acoustic paths enabling bi-directional measurement independent of flow profile for superior accuracy, even under challenging flow profile conditions.

- Capable of identifying process changes or liquid pollution via the velocity of sound.

- Features a fully welded construction, ensuring no pressure loss and maintenance-free operation.

- Available with both flange and welded connections for versatile installation options.

- Equipped with enhanced diagnostics and offers various digital communication options for seamless integration into your system.

Based on the transit time method, the 3 parallel acoustic paths of the flowmeter allow bi-directional measurement independent of flow profile for high accuracy even under less favourable flow profile conditions (e.g. short inlet and outlet runs). By means of the velocity of sound, the device is also able to identify process changes or liquid pollution. Its fully welded construction does not cause any pressure loss and is maintenance-free. The OPTISONIC 3400 is available with flange as well as welded connections. It features enhanced diagnostics and provides various digital communication options.

Krohne Altosonic V12- Custody Transfer Meter- Gas

The ALTOSONIC V12 stands as a cutting-edge 12-chord ultrasonic custody transfer (CT) flowmeter engineered specifically for natural gas applications.

Key Features of the ALTOSONIC V12:

- Engineered for optimal measurement accuracy, certified to OIML R137 class 0.5 by NMi, ensuring precision even in less-than-ideal field conditions.

- Ideal for high-accuracy gas volume flow measurement applications across various industrial settings, offering dedicated versions for conductive or non-conductive liquids.

- Designed to withstand extended process temperature ranges and available in low or extreme pressure ratings.

- Direct path configuration eliminates the influence of scaling, ensuring consistent performance.

- Features extensive sensor and process diagnostics, including NE 107 compliance.

- Optional heating jacket available for enhanced functionality.

- Full bore design with no moving parts, ensuring minimal wear and pressure loss.

- Offers various digital communication options for seamless integration into your system.

- Available in compact or field-mounted versions, with optional cable lengths up to 30 m / 90 ft and IP68 rating for added flexibility and durability

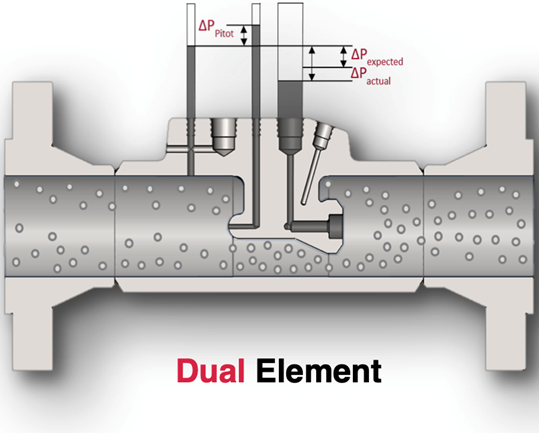

Dynamic Flow Computers, Inc.- Dynacone

The DynaCone stands at the forefront of innovation as a state-of-the-art Dual Element Wet Gas flowmeter, combining field-proven hardware with cutting-edge software for unparalleled performance. It offers an integrated solution tailored to effectively tackle your allocation metering challenges.

Key Features of the DynaCone:

- Compact design and robust construction ensure reliability in various environments.

- Utilizes non-radioactive components, prioritizing safety and compliance.

- Requires only basic field configuration, minimizing the need for frequent recalibrations or field tuning.

- Designed for trouble-free wellhead flow measurement or potential separator replacement, providing operators with the ultimate “Life-of-Field” solution.

Applications: (TypeI/II Wet Gas)

DynaCone wet gas meter provides high quality, reliable data for flow assurance, reservoir, production allocation and process management.

- Wellhead gas/condensate production surveillance: TypeI/II wet gas flow measurement

- Gas injection/liftoptimizationGas

- High value upstream processing lines

- Test Separators

- Group production monitoring at the production header & compressor stations

- Steam Measurement

Dynacone Manuals

EPI MXTM

Thermal mass flow meters adhere to King’s Law, leveraging convective heat transfer principles to accurately measure mass flow. The MXTM Thermal Mass meter is meticulously crafted to accommodate a diverse array of flow ranges and gas compositions. Our Insertion Style Thermal Mass Flow Meters feature a sensor & probe assembly inserted into the process gas flow conduit, facilitating the flow of process gas across the flow sensing element. Available with 1/2″, 3/4″, or 1″ OD probes, our insertion style flow meters offer optional mounting items such as tube fittings, flanges, and ball valve retractors.

EPI MXTM is ideal for low pressure flow measurement applications:

- RTD for Temperature compensation and output

- Modbus RS485 Digital Output

- 4-20 mA Output

- Pulse Output

- Easy set-up with Zero Calibration through Display

- Explosion Proof Area Classification

- High Accuracy Measurement

For sales and support, call 844-674-7466